I attended a East Tennessee Region Rallycross earlier this year. They were using a pneumatic timing switch instead of a stopwatch. It seemed to be working very well. The Middle Georgia Region where I live just started a Rallycross program but had been using stopwatches for timing. The pneumatic switch is a much easier method than the stopwatch.

So, I contacted Ted Visscher who had built the system East Tennessee Region uses. He shared some links to information for building the switches. This link http://www.sccabb.com/forum_posts.asp?TID=9223 was a good start. It led me to this link http://detroit-scca.org/e107/request.php?605. The Detroit Region had designed a pneumatic switch and posted how they built it. This was the switch setup I was looking for.

I started looking for the parts on the internet and found the suppliers listed below in the parts list below. I posted the prices I paid for the parts as a reference. They may be available cheaper by other vendors.

Pneumatic Timing System Parts List

QTY SIZE SPECIFICATION COST SOURCE

2 #32NO-WB Switch $56.72 Kleen-Rite Corp.

2 1/2″ Wire Clamp $1.00 Ace Hardware

4 2 Contact Connectors Hopkins 47965 $5.98 Autozone

60′ 3/8″IDx5/8″OD Rubber Hose $52.34 Kleen-Rite Corp.

4 3/8″ Hose Plug Free Fabricated

4 1/4″x2″ Eyebolt $3.16 Ace Hardware

10 5/8″ Hose Clamps $4.50 E-Bay

2 3/8″ Brass pneumatic “T” $13.98 Ace Hardware

4 8″-10″ Tent Stakes 86565 $3.89 Ace Hardware

4 21″ Rubber Bungees $3.52 E-Bay

2 35 Qt. Sterilite Latch Tote $18.00 Family Dollar

2 RJ45 Computer Connector Free Donated

250′ Cat-5 Computer Cable Free Donated

$160.09 Total

Then I looked up the Axware forum online at http://www.axwaresystems.com/forum/viewtopic.php?f=4&t=795 . I learned from it that the Axware System hardware requires a normally closed circuit for the trigger. So, the pneumatic switch needed a circuit to convert the normally open contacts to a normally closed signal for the Axware box.

They had a circuit they had designed using a Mosfet as a switch to convert from a normally open to a normally closed switch signal at http://www.raceamerica.com/download/techsup/antmr001.pdf. It looked simple, so I built one for each switch inside a plastic electrical outlet box.

I hardwired some Cat-5 cable into the box to plug into the Axware System box with RJ45 connectors. The circuit is powered by a 12v AC/DC wall wart that I hardwired to the circuit. The pneumatic switches connect to the box using a cable made as shown on the Axware drawing at http://www.raceamerica.com/download/techsup/ancbl002.pdf .

Below is a listing of the parts I bought to make the normally closed circuits.

Normally Closed Circuit for Axware Box

QTY SIZE SPECIFICATION COST SOURCE

2 IRF-510 Mosfet 276-2072 $4.98 Radio Shack

2 10K Ohm 1/4W Resistors 271-1335 $1.49 Radio Shack

1 120V/12V AC-DC 55057391 $11.99 Radio Shack

1 Single Outlet box Plastic $0.59 Ace Hardware

2 RJ45 Computer plugs Free Donated

1 Outlet box cover with 2 RJ45 sockets Free Donated

4 ft. Cat-5 Cable Free Donated

$19.05 Total

We tested the system at a Middle Georgia Region Rallycross on 03/15/2014. It worked well, but we were getting some false tripping and the Axware system would loose track if we launched more than one car at the time. We started using a stopwatch as a backup to the system to avoid too many reruns.

I am working on some ideas that may fix those issues. I plan to try adjusting the sensitivity of the switch which may reduce the false triggers. I also plan to put some baby powder in the air line to keep it from sticking together inside.

One thing we tried by the end of the day was to lessen the tension on the air line. This allowed the diameter of the line to say larger which seemed to help during the fun runs.

With some adjustments, we should end up with a system that is very reliable.

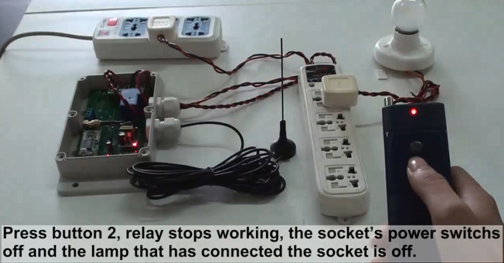

I am working an improvement which will make the system much easier to use and set up. I found some wireless switches online at http://www.rfcontrolsystem.com/ . They offer a two channel receiver with a transmitter. The combo can be ordered with a short or long range capability and with an extra transmitter. Each transmitter can be set to operate a separate relay inside the receiver. The relays have normally open and normally closed contacts. So, I ordered the parts below and began construction once they arrived. It took about three weeks to get here from China.

Radios & Delay/Latch Circuit

QTY SIZE SPECIFICATION COST SOURCE

2 IRF-510 Mosfet 276-2072 $4.98 ourautomation.com

1 2CH 2000M Transmitter & Receiver $50.00 ourautomation.com

Kit 0020213

(S2U-DC06/09/12/24-ANT2 & CB-2)

0021045 (CB-2N)

(This Transmitter would also work and is cheaper at $22.00 0021024 (CB-2))

0010124 (A-02)

2 IRF-510 Mosfet 276-2072 $4.98 Radio Shack

2 220uf 35V Capacitor 272-1029 $2.98 Radio Shack

2 10K Multi-turn Pot 271-0343 $5.98 Radio Shack

2 9V Battery Clip 270-0324 $2.99 Radio Shack

$135.90 Total

I ordered one transmitter with leads already coming out of the transmitter to see if it could be attached to directly to the pneumatic switch. It did work, but not well. The transmitter was programmed to trigger once a second for four seconds to ensure that when the wires were connected through a switch that the signal was received by the transmitter. That would cause issues for the Axware box.

I decided to attach the switch directly to the circuit board in parallel to the push-button switch to see if that would work. It also worked, but again not well. If the pneumatic switch was not held closed for about a half second, the receiver would not trigger the relays. So, I needed a way to keep the signal from the pneumatic switch closed longer to ensure the receiver would trigger the relays.

I found a circuit at http://easy-electronics4u.blogspot.com/2012/02/simple-dc-timer-using-mosfet-onoff.html that allows a delay to be used with another Mosfet circuit. I used the equations they provided to calculate a circuit that can be kept closed for about .5 seconds to 3.5 seconds and is adjustable.

That is why there are several parts from Radio Shack in the list above.

Here is how the transmitters were rewired and the latching circuit added to the system.

The battery springs were removed by bending the tab back and forth until they snapped off. One of the two push button switches were shorted using a jumper soldered directly to the circuit board.

I found two old car chargers and cut the cords for use to attach the transmitters to the pneumatic switches. These attach directly to the transmitters at one end and to a two prong plug at the other that matches the plugs on the switches.

I built the circuits by soldering the legs of the capacitor and trim pot. as shown. Then I attached wires as shown and soldered the legs of the Mosfet into the circuit. Leaving the circuit are three wires. There is a B+, Ground and switched lead. The cardboard is to separate my added parts from the circuit board.

The switched lead is attached to the ground terminal on the transmitter. B+ from the battery is attached to the B+ terminal on the transmitter. Then a lead is soldered onto the on/off switch and run to the latch circuit B+ lead. This allows the transmitter battery to be turned off to save the batteries.

The 9V battery clips attach to the battery since the springs for the battery connections were removed. Note the batteries will not fit back into the transmitter, so they were just taped on so the batteries can be replaced as needed.

The circuit triggers the receiver every time I tried it. The latch holds closed for about a second so I did not even adjust it. Funtional testing will have to wait until I can borrow the timer and laptop after the next autocross.

We got to test the timer using the radios on Saturday 04/05/2014. It worked during testing but we did have a few issues. While the transmitters were close to the receiver, it worked every time. However, when we moved about 100 yards away, the receiver did not work every time. Since there were trees and other obstructions we decided it worked well enough to test it at the next Rallycross on 04/26/2014.

Before then, I will find a small metal plate to attach the receiver antenna’s magnetic base to keep it standing vertically. That may help since the receiver antenna was mounted horizontal on the table leg during our first test. I may also use a piece of PVC pipe to set the transmitters in so their antennas will stay vertical. The radios are supposed to be good for 300 meters.

The latch circuits seemed to do the job and the receiver was working well when we had signal. The Axware Timer also seemed to accept the inputs without issue.

More to come after the next Rallycross.